To understand the differences between Schedule 10 and schedule 40 steel pipes, the first thing to be clear about is what schedule is and what Schedule 10 and schedule 40 steel Pipes are.

What is schedule?

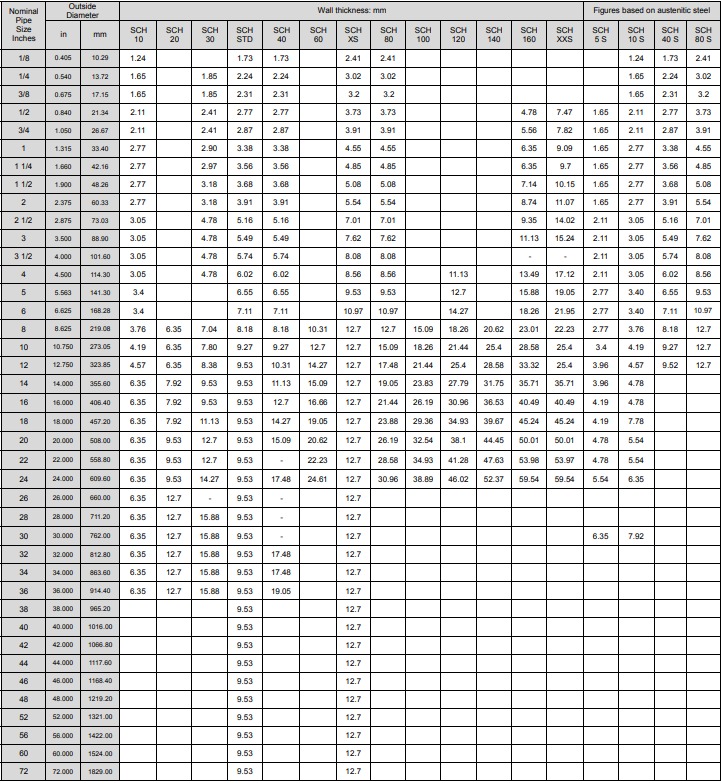

Schedule (SCH) represents the wall thickness grade of steel pipes and is determined in accordance with the ASME B36.10 (carbon steel pipes) or ASME B36.19 (stainless steel pipes) standards. It does not directly represent the value of the wall thickness, but rather a series number, whose corresponding value varies with the nominal diameter (NPS).

What are Schedule 10 and schedule 40 steel Pipes?

SCH 10 and SCH 40 are the representation methods of the wall thickness grades (Schedule) of American standard steel pipes. They reflect the relative wall thickness of the pipes, but not the specific values of the wall thickness. Other common wall thickness grades include: SCH 5, SCH 20, SCH 30, STD, SCH 60, SCH80, XS, SCH 100, SCH120, SCH160, XXS.

SCH 10 indicates a pipe grade with a relatively thin wall thickness, typically used in ventilation ducts and low-pressure chemical systems. SCH 40 represents a pipe grade with a medium wall thickness, which is the most common and frequently used pipe grade, mainly applied in building water supply, oil and gas, and industrial pipe networks.

The main differences between Schedule 10 and schedule 40 steel Pipes

After understanding the definition of SCH and what Schedule 10 and schedule 40 steel pipes are, I will take you to understand the differences between Schedule 10 and schedule 40 steel Pipes.

1. The difference between wall thicknesses

CH 10 is thinner than SCH 40. For example, NPS (Nominal Diameter) is:

½ "SCH 10 ≈ 1.65 mm, SCH 40 ≈ 2.77 mm

2 "SCH 10 ≈ 2.11 mm, SCH 40 ≈ 3.91 mm. Under the same nominal diameter, the inner diameter of SCH 40 is smaller, the outer diameter is the same but the wall thickness is larger. For more comparisons of wall thicknesses, please refer to the chart:

2. Differences in pressure-bearing capacity

The wall thickness directly affects the maximum allowable working pressure. Under the same nominal diameter, the wall thickness of SCH 40 steel pipe can withstand higher pressure, while SCH 10 steel pipe can withstand less pressure and is suitable for low-pressure scenarios.

3. The weight and ease of installation are different

SCH 10 steel pipe requires less material, so it is lighter in weight and easier to handle and install. Under the same circumstances, SCH 40 steel pipe is heavier, and the difficulty of handling and installation during construction increases, but the structure is stronger and more durable.

4. Differences in cost

SCH 10 steel pipe requires less material, has a relatively low price, and is more convenient during transportation, reducing the cost of materials and transportation. SCH 40 steel pipe, due to its large wall thickness, requires more materials and increases the cost. Moreover, its weight is relatively large, and the transportation and installation costs will also increase significantly. However, it is strong and durable and has a significant advantage in structural reliability.

Selection suggestions

If your project is a low-pressure, light-load, and budget-limited scenario, and the size is large (such as fire main pipes, large-diameter ventilation, etc.), SCH 10 steel pipes can be considered.

If higher pressure resistance, more reliable structure and longer service life (especially for industrial or building water/gas systems) are required, SCH 40 steel pipe is recommended.